Cross-border e-commerce overseas warehouse (OMS): inventory locking and release, and some understanding of in-transit inventory

Editor’s lead: In cross-border e-commerce OMS system, inventory is also very important, and reasonable inventory design is helpful to ensure the normal operation of OMS outbound. So how to deal with the locking and releasing of inventory? In OMS, how should the change of online inventory be added into the scope of design consideration? Let’s take a look at the author’s summary.

OMS issue documents will have several key nodes, and the corresponding logic needs to be completed at different nodes to ensure the subsequent normal circulation of documents.

In cross-border e-commerce OMS, the key points are: logistics ordering, freezing of withholding funds, locking, release and deduction of inventory, etc. An article has been written before logistics ordering.This time, let’s talk about locking, releasing and deducting inventory..

For cross-border e-commerce overseas warehouse OMS, there are generally several scenarios for inventory locking:

- Lock the inventory when it is created;

- Place an order for logistics, and lock the inventory when obtaining the logistics list;

- Lock the inventory when submitting the outbound order to WMS.

There will be different business scenarios for different customers, so the inventory locking is generally different. These three scenarios are not optional, but all three, and they should be flexibly combined.

If some customers are strict and want to occupy some inventory when creating the outbound order, they will lock the inventory after creating it.

Some customers have no special requirements for inventory locking, so the normal situation should be to lock the inventory when they get the logistics list.

There are also some customers who may upload their own logistics sheets or do not require logistics sheets, so they can set to lock the inventory when submitting the outbound order to WMS.

It is suggested that the timing of inventory locking should be made into a policy rule. Every time a different customer is introduced, the corresponding rule can be configured. If there is no configuration rule, the default node will be adopted, which can flexibly take into account the needs of different customers.

With the lock of inventory, there will naturally be the release of inventory. In fact, the locking and releasing of inventory can be divided into two groups. The first group is locking and releasing, and the second group is locking and deducting.

The inventory is locked, which means that the outbound order occupies this part of the inventory, and the system needs to mark it as locked to prevent it from being preempted by other outbound orders. So if I cancel the outbound order, I need to release the lock of this block, so the corresponding release of inventory lock actually refers to the scene where the outbound order is cancelled or intercepted.

If this outbound order is completed, the corresponding inventory needs to be deducted. At this time, the locked part will be converted into the deducted part, which is equivalent to emptying the locked quantity first, then increasing the deducted quantity (inserting the inventory flow), and finally the available inventory will remain unchanged.

Schematic diagram of inventory locking and release

Here we need to pay special attention to two issues, one is the timing of release, and the other is the quantity of release.

Regarding the timing of release, for the cancellation or interception of the outbound order, when the cancellation or interception is successful, then release it. For the normal issue of outbound order, we need to pay attention to one question:How to define outbound?

On the surface, the goods leave the warehouse, which is called outbound. However, in the actual business scenario, it may take a day or two for the goods to be picked up by the logistics provider after picking and packaging, and the outbound node will be late at this time. It may also be taken away by the logistics provider, but there is no rigorous handover action, resulting in some outbound documents not marked as outbound, so they have been in a state of waiting for outbound, and inventory cannot be deducted.

How WMS defines outbound will affect when OMS deducts inventory, so this piece needs to be combined with business to explore an optimal solution. If the "delivery" is too early, the time period for customers to intercept the delivery will be very short, and the actual goods will not go out, but they cannot intercept the delivery, which will increase losses in vain; If "outbound" is too late, it is possible that some outbound documents will be marked as overtime outbound, which will affect the rating of platform stores.

Regarding the quantity released, for overseas warehouses of cross-border e-commerce, there is basically no so-called partial outbound or multi-batch outbound, and most businesses are issued in a single order and completed at one time. So don’t expand here, just make a reminder.If the issue quantity does differ, it is necessary to ensure that the actual available inventory quantity is accurate in consideration of the locked quantity, and the difference can be adjusted by some exception handling methods.

In-transit inventory is a link that is easily overlooked by everyone. Sometimes, I even feel that this data is useless, and then I forget that there is such a thing when designing some logic.

I’ve been looking for information about in-transit inventory on the internet for a long time, and it turns out that many articles seem to be shallow or complicated, which makes it particularly uncomfortable to understand.

Here, I would like to sum up how the in-transit inventory in overseas warehouses of cross-border e-commerce is generally used within my personal knowledge. It is only my personal opinion, so please pay attention to dialectical treatment.

If you want to simply understand the in-transit inventory, it is enough to analyze it directly from the two most common ways to produce the in-transit inventory. They are:

- Allocation is on the way;

- Purchasing is on the way.

Transfer in transit is the in-transit inventory generated in the process of transferring from warehouse A to warehouse B. For warehouse a, the goods have left warehouse a, so the inventory of warehouse a has been deducted; For warehouse B, the goods are on the way to transport, but they have not been put into storage yet, so they cannot be counted as available inventory, but only in transit.

There are many similarities between purchase in transit and transfer in transit, both of which are sent from one place to another. It’s just that the purchase involves some settlement problems with external suppliers, so it’s a little troublesome. For the warehouse that is about to receive the purchased goods, the goods are still on the road and have not been put on the shelves, so it can’t be counted as available inventory, but only in transit.

In-transit inventory can estimate the inventory in the future for a period of time to guide the sales decision; In-transit inventory will also occupy the cost of capital, so the financial department will pay attention to and attach importance to this piece of data.

For cross-border areas, because the process of stocking goods to overseas warehouses (the first journey) takes a long time, the controllability of in-transit inventory is particularly important for sellers. In addition to counting the actual available inventory of each overseas warehouse, we also need to pay attention to this part of the inventory in the process of stocking, and make an inventory plan in time.

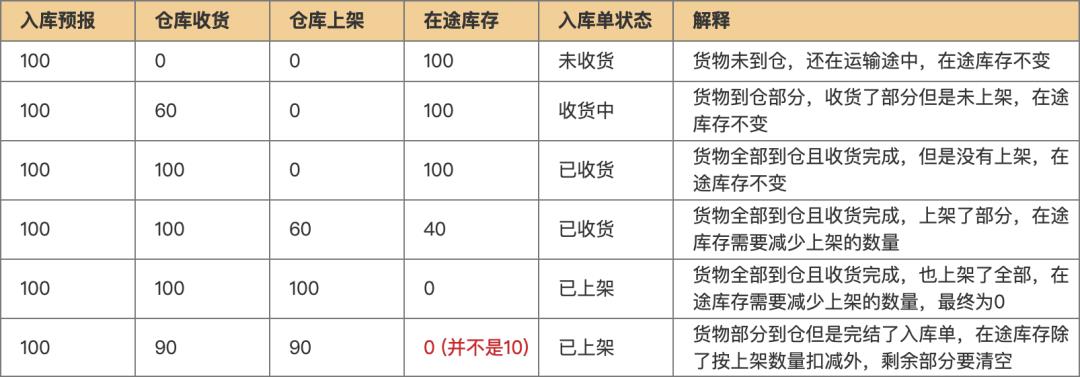

For OMS, the definition of in-transit inventory generally refers toAfter the receipt document is submitted to the warehouse, but before the warehouse receives the goods, the total inventory in this period of time..

If the warehouse is actually put on the shelves, the in-transit inventory will be converted into available inventory. If the actual receipt of goods in the warehouse is less than the forecast quantity, but the receipt document is forced to end, then the inventory in transit needs to be reduced accordingly. Because the receipt document has been closed, the in-transit inventory should be converted into available inventory according to the actual quantity on the shelves, and the extra part should be invalidated and released because it can no longer be put on the shelves.

Schematic diagram of inventory change in transit

For OMS, it is important to pay attention to the number of SKUs whose receipt status is submitted between shelves. This part needs to dynamically adjust the number of in-transit inventory according to the actual number of shelves fed back by the warehouse, and finally pay special attention to some nodes of differential receipt and differential shelves.

In OMS outbound, the logistics ordering and rule engine are the most complicated, and the locking and releasing of inventory is the most basic requirement, so I didn’t write anything too deep, just briefly summarized and reviewed the past project experience.

In fact, the logic of locking and releasing the inventory is the same as that of withholding fees from the issue document. After locking the inventory, the corresponding fees will be frozen, and after releasing the inventory, the frozen fees will be released or deducted accordingly. It’s just that the content involved in billing is partial and the content is miscellaneous, so I won’t talk much here.

And the inventory on the way is because there are really too few online materials, so I made a fool of myself again and output some of my own shallow views and opinions.

I hope this article can help you. See you next time!

My name is Vitamin, and WeChat WeChat official account: PM Vitamin. Former PHPer, who has worked as an online education product and a cross-border warehousing and logistics product for three and a half years, is currently a supply chain product manager in the field of foreign trade SaaS. Mainly focusing on WMS/OMS/TMS/BMS/ERP and other fields, sharing product knowledge related to supply chain.

This article was originally published by everyone as a product manager, and it is forbidden to reprint without the permission of the author.

The title map comes from Unsplash and is based on CC0 protocol.